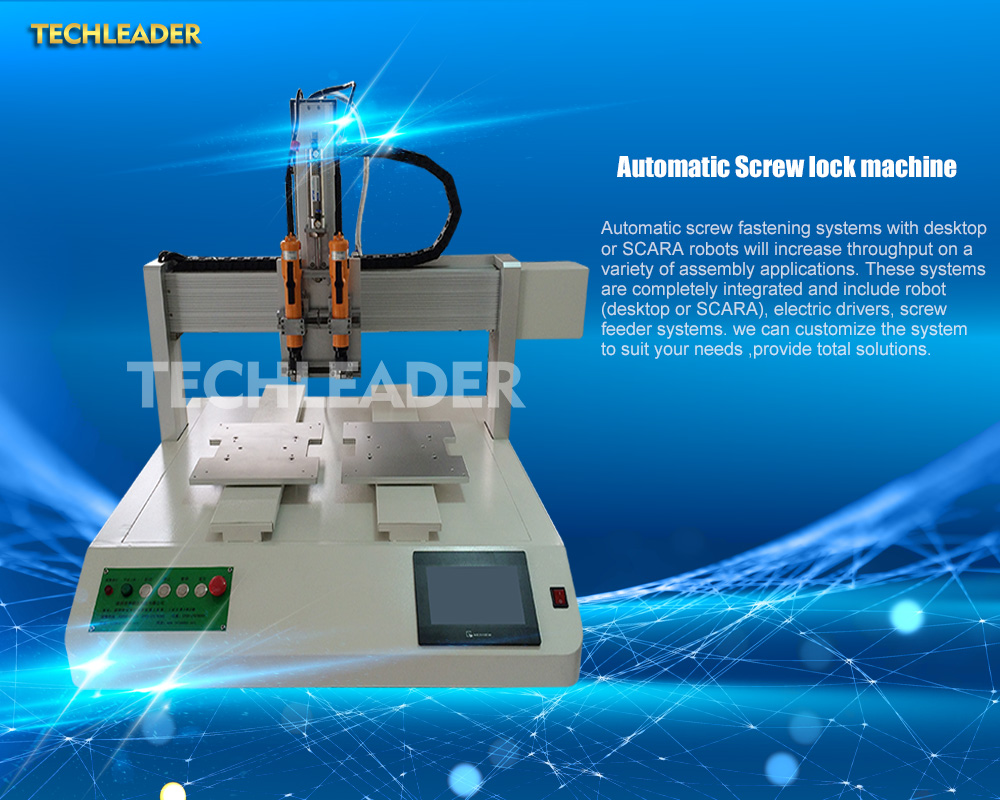

An Automatic screw locking machine work wonders when they are installed as part of a Company’s Automated Assembly Line, the improved productivity times and efficiency.

When a Company is looking to make the transition to an Automatic Screw Locking Machine they are faced with the questions of “What will be used for” and that inquiry has two possible answers.

- Tailored made Automatic screw locking machine for a specific type of Automated Assembly Line for the manufacturing of a particular part of your product.

- A flexible Automatic screw locking machine dedicated to a wide array of processes along the Automated Assembly Line.

Regardless of your pick from the answers above, an Automatic Screw Locking Machine must always serve three principles purposes in an Automated Assembly Line, Assembly, Transmission, and supplying spare parts. The most important one of all three is the “transfer” as it determines the level of automation of the Assembly Line at all stages of the Manufacturing process.

For a Tailored made Automatic screw locking machine it has to be placed in a strategic workstation along the Assembly Line, so the machine can perform its functions uninterrupted, which in turns increases efficiency along the entire Assembly Line, and thus, increasing the Profits margin the Company can get from the product being manufactured. A single Machine can perform simultaneous works along different workstations, although this greatly depends on the Model the Company is purchasing. In order to enhance the performance of the Assembly Line, the Workstations that will be using the Automatic screw locking machine will have to be specially accommodated in order to fit the needs of the Machine.

Advantages of using a Tailored made Automatic screw locking machine.

- The Working sequence of the Machine through multiple workstations can be easily programmed by the Operator, the System’s designer or the Production Engineer. It is also the best option for Automated Assembly Lines devoted to Mass production.

- The Machine can easily be integrated into a fully automated assembly line who uses robotic arms rather than workers. As both the Machine and the Robotic Arms can be easily programmed the integration is very simple and it will turn the entire Assembly Line fully Automated. As long as the Machine’s maintenance is up to date it will work smoothly.

Advantages of using a flexible Automatic screw locking machine dedicated to a wide array of processes along the Automated Assembly Line.

When the Assembly Line requires that the Automatic Screw Locking Machine perform a series of different process, like using different screws on a single Item through multiple Workstation, then this is your best option. The entire installation process and configuration can be accomplished quickly without causing any delays to the Assembly Line and bringing a full Automation to it.

This flexibility is due to “Modules” that are placed along the Production Line, but they are all still part of the same machine.

If you are the Production Engineer in charge of searching for the proper Automatic Screw Locking Machine for your assembly line, you have to be sure that you fully understand the needs of your Company.

If you need one Tailored made Automatic screw locking machine, please via our website https://www.automaticchina.com/

For more info about the automatic screw locking machine,please kindly contact us as below:

Contact:

Person: James Yuan

Company: Huizhou Shengyang Industrial Co., Ltd

Add: 5th Floor,D Building,Jintaiyang Industrial Zone,Xingye Road,Zhongkai District,Huizhou,Guangdong,China

Tel: 86-752-6682869

Mobile:+86-13352636504

Email: info@automaticchina.com

Site: https://www.automaticchina.com/product-category/automatic-screw-locking-machine/

Person: James Yuan

Company: Huizhou Shengyang Industrial Co., Ltd

Add: 5th Floor,D Building,Jintaiyang Industrial Zone,Xingye Road,Zhongkai District,Huizhou,Guangdong,China

Tel: 86-752-6682869

Mobile:+86-13352636504

Email: info@automaticchina.com

Site: https://www.automaticchina.com/product-category/automatic-screw-locking-machine/